- Precious metal refining systems for E-WASTE

- Precious metal refining systems for Catalytics

- Gold Refining And Extraction Equipment

- Precious metal refining systems

- Pt/Pd/Rh purification system equipment

- High efficiency gold electrolytic unit

- High efficiency silver electrolytic unit

- Smelting ingot system equipment

- Fume treatment system

Precious metal refining systems

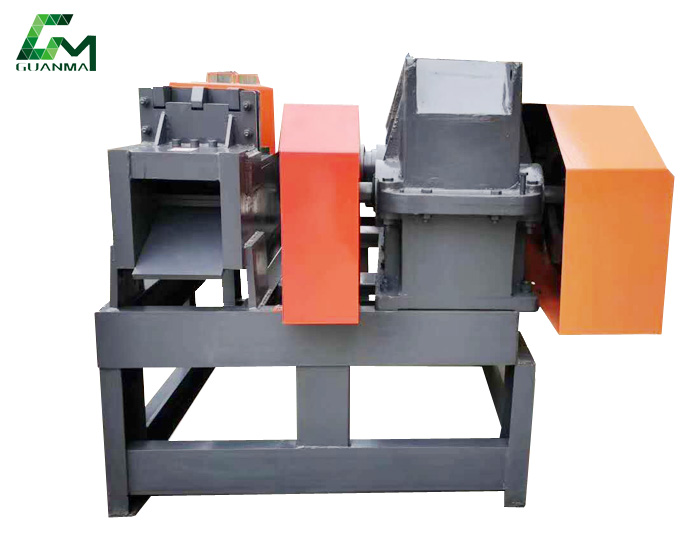

- Product Introduction:

Production:100-300kg/day

Purity:≥99.95%

Utilization rate:≥99%

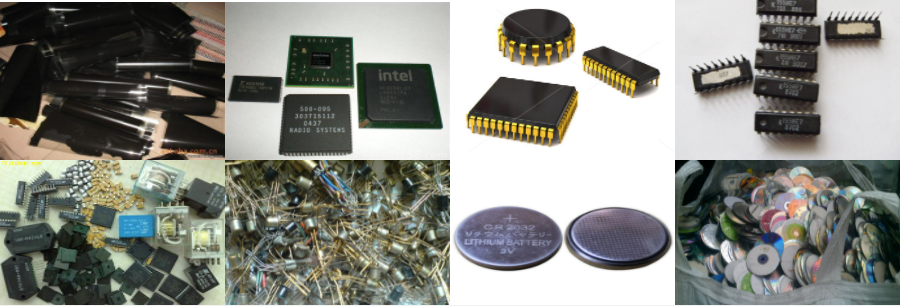

Applicable materials:chips,north and South Bridges,memory chips,integrated circuits,plastic components,anode mud,etc

Video Description:

PRODUCT DESCRIPTION:

The precious metal recovery&refining plant is used to extract precious metals such as gold,silver,palladium and platinum from electronic waste precious metal chip components and anode slime,and the purity of extracted precious metals can reach 99.99%.Its raw materials mainly come from waste mobile phone circuit board,computer CPU,motherboard ,VCD,CD,TV,game machine,fax machine,telephone,mobile communication and other household appliances;

Technical Parameter:

|

Model |

Capacity(Kg/Day) | Total Power(Kw ) | Rate Purity | Purity |

|

GM-100 |

100-200 | 20 | ≥99% | ≥99% |

|

GM-200 |

200-300 | 30 | ≥99% |

≥99% |

There are alsoleftover materials from electroplating factory,electronic component factory,printing factory,photosensitive materials factory and electronic factory.

Raw Materials:

Final products:

Production Process:

1.Dispensing the gold stripping solution;

2.Put the surface plated materials into liquid,then the surface gold dissolved in the gold stripping solutions,no other metal like lead,nickel,iron,or any other metal be dissolved in the solution.(our patent product);

3.Filtering to remove the impurity;

4.Reduction:Add the reduction powder to the solutions,the gold will be extracted and turn into black powder,Get the black powder settle down,then finally we get the crude gold powder.

Features

1.After processing waste water emissions remain the same;

2.The recycle rate of gold,sliver,platinum,palladium can get more than 97-99%;

3.The purity of the precious metal can get 99.99%;

4.Full Automatic,saving the labor cost;

5.The process is short,use the hydro metallurgical without cyanogens technology,reduce pollution to the environment.

Customer Case:

ABOUT US:

Contact Us

If you have any requirement or suggestion, please fill in the form and send to us,or contact us by E-mail :kelly@gmznjx.com thanks!

.png)