- E waste circuit board recycling plant

- PCB disassembly equipment

- Cable Wires Recycling Machine

- Lithium battery recycling plant

- High efficiency gold electrolytic unit

- High efficiency silver electrolytic unit

- NOx waste gas treatment equipment

- Copper Electrolysis Machine

- Chemical refining system of precious metals

- Smelting ingot system equipment

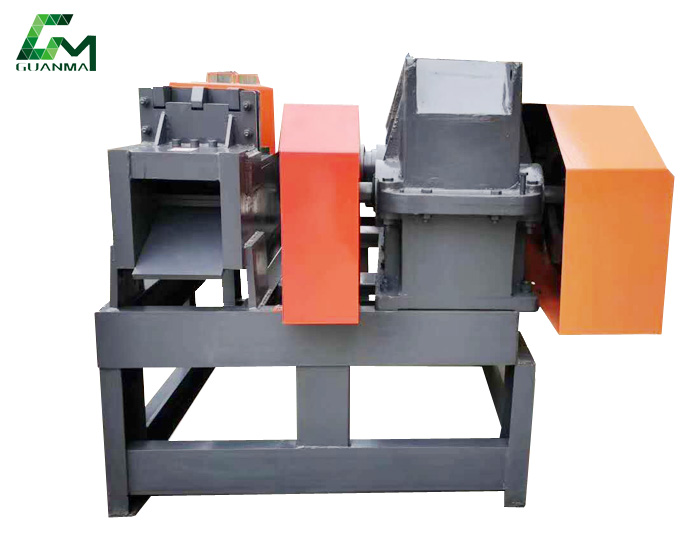

E waste circuit board recycling plant

- Product Introduction:

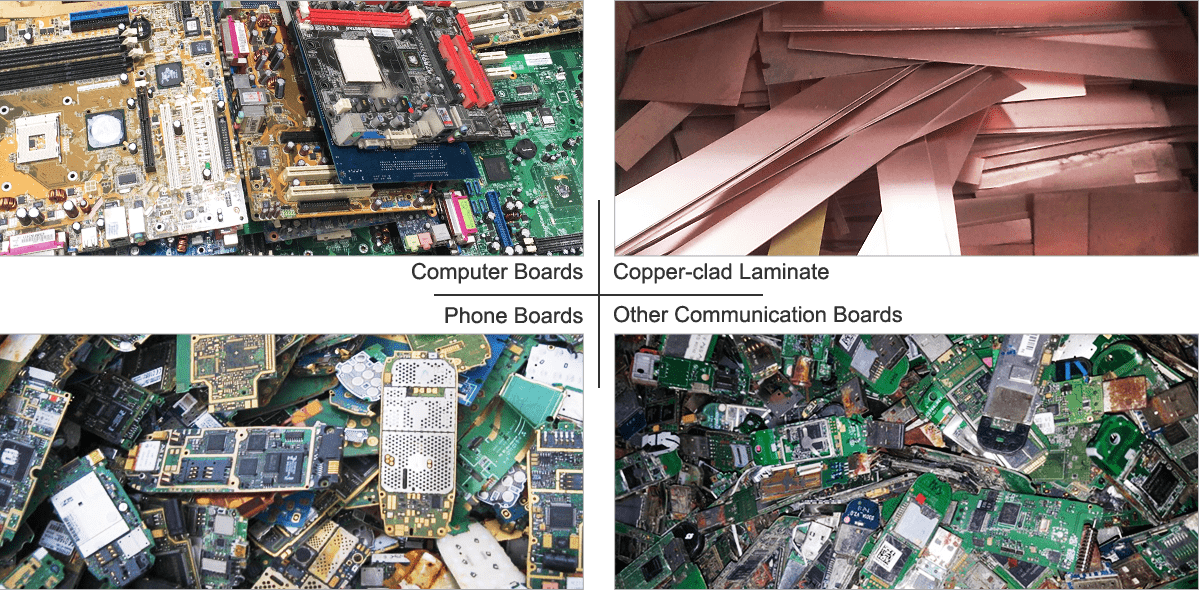

E waste circuit board recycling plant is suitable for circuit board, copper cladding plate, PCB , mobile phone board, etc., to recover the nonferrous metal copper, gold, silver, palladium, platinum and rhodium in the waste circuit board. The whole equipment separates the copper and resin in the circuit board through physical crushing.

Video Description:

PRODUCT DESCRIPTION:

E waste circuit board recycling plant is suitable for circuit board, copper cladding plate, PCB , mobile phone board,

etc., to recover the nonferrous metal copper, gold, silver, palladium, platinum and rhodium in the waste circuit board.

The whole equipment separates the copper and resin in the circuit board through physical crushing. At the same

time, the equipment is also equipped with pulse dust removal equipment to effectively solve the dust generated in

the production process. The subsequent use of high voltage electrostatic sorting machine, make sorting more fine

and efficient, effectively control the loss of non-ferrous metals, and metal sorting rate up to 98%.

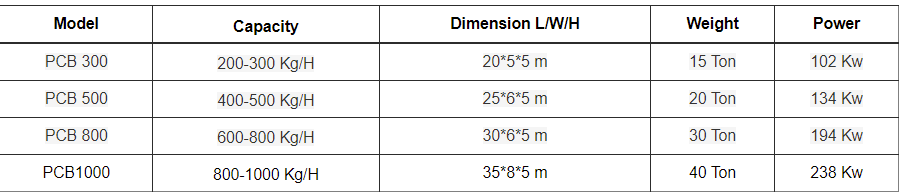

Technical Parameter:

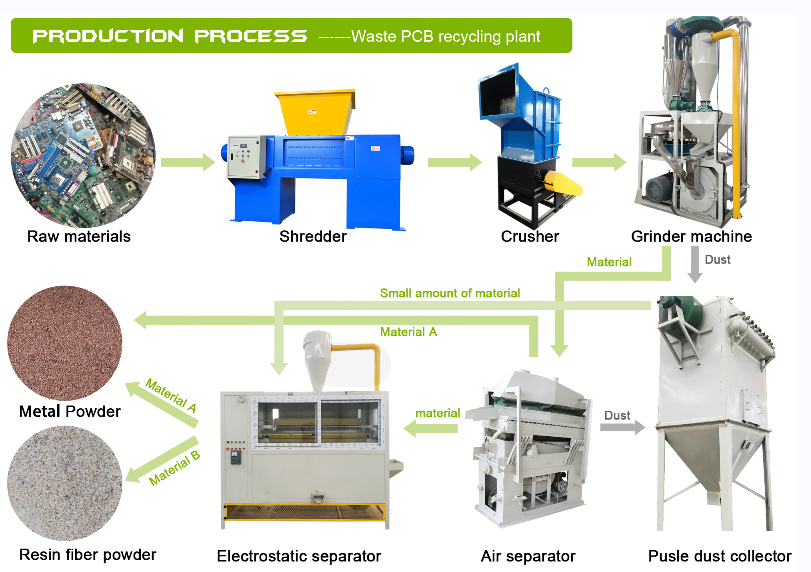

Flow chart:

The first breaking machine adopts biaxial shredding type,the second breaking machine adopts hammer pulverizer,

and the third breaking machine adopts high-speed turbine pulverizer.Then a process route to separate the metal

from the resin by wind and electrostatic separation.In order to prevent dust pollution in the process of production,

a pulse dust removal device is added after the wind separation process to effectively solve the problem of dust

pollution.

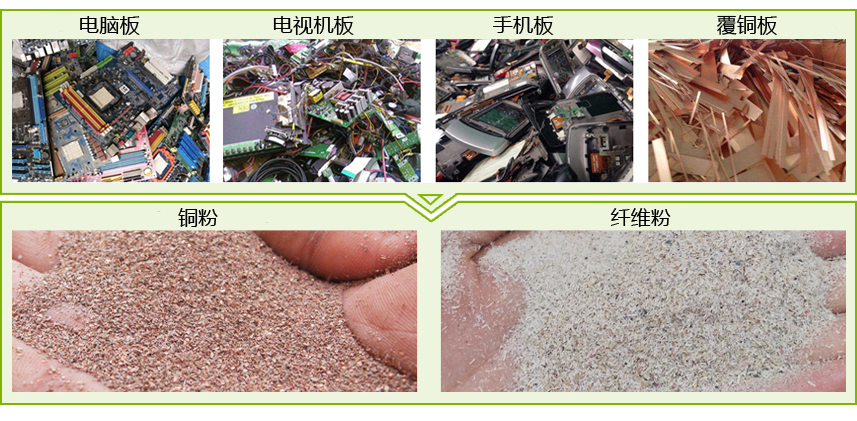

Raw Materials:

Final Product:

Product advantages:

1, Compact structure, reasonable layout, stable performance, low noise.

2. The recycling equipment of waste circuit board adopts two stage crushing, which can make the processing capacity reach

800kg per hour.

3. The whole production line adopts negative pressure feeding to effectively reduce dust overflow.

4. The sorting rate of airflow sorting equipment is up to 97%.

5, High voltage electrostatic separator makes sorting more fine and efficient, effectively control the loss of non-ferrous metal.

6. Equipped with magnetic separation function, iron can be separated from the material.

7. The waste circuit board recycling equipment adopts PLC to control the complete production line for uniform feeding and

coordinated operation.

8. The grinding chamber adopts circulating water temperature control and noise reduction.

9, The return system makes crushing more efficient.

10. The efficiency of pulse dust removal equipment is as high as 99%, which effectively inhibits dust volatilization

Customer Case:

ABOUT US:

Contact Us

If you have any requirement or suggestion, please fill in the form and send to us,or contact us by E-mail :kelly@gmznjx.com thanks!

.png)