- PCB disassembly equipment

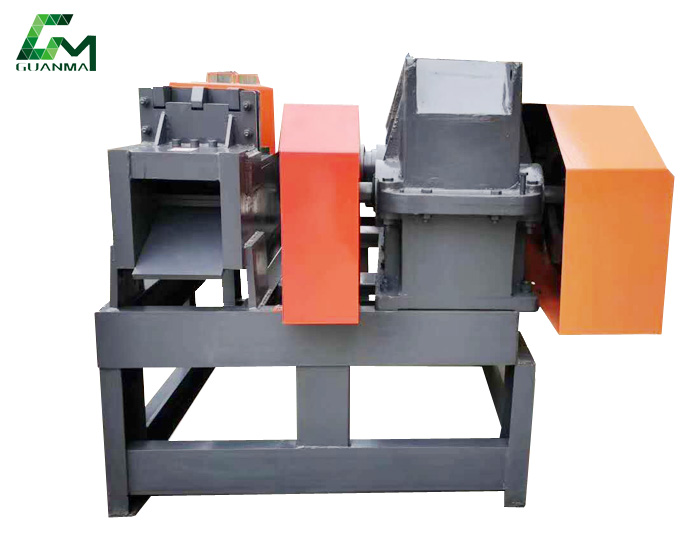

- Cable Wires Recycling Machine

- Tire Recycling Equipment

- Semi-Automatic Tire Recycling

- Continuous Pyrolysis Plant

- Tyre Pyrolysis Plant

- Aluminum plastic separation plant

- Double shaft shredder machine

- Waste Refrigerator recycling plant

- Single Shaft Shredder

- Plastic PVC/PET Separator

- Aluminum Eddy Current Separator

- Building Wire Straightening Cutting Machine

Cable Wires Recycling Machine

- Product Introduction:

Capacity:200-1000 kg/h

Raw Materials:old communication wires,car wires,computer wires,telephone wires,household electrical wires,etc

Final Products:Copper particles, plastic particles

Video Description:

PRODUCT DESCRIPTION:

Cable Wires Recycling Machine is used to recycle waste cables with diameters less than 20mm,such as automobile line,car line,computer line,motorcycle line,communication line,etc.Cable recycling equipment is composed of three parts:knife crusher,airflow separator,pulse dust collector.Airflow sorters work based on the different gravity and density of copper and plastic.Its production line layout is reasonable,reduce personnel costs,its recovery rate is as high as 99%,and the separated copper and plastic particles,can be directly marketed and sold,high economic benefits,easy to operate.Copper is more than 99%pure.

Technical Parameter

|

Model |

Power(KW ) | Weinht(kg ) | Capacity(kg/H) | Dimension(m) |

|

GM-400 |

39 | 2000 | 100-300 | 2*2*2.3 |

|

GM-600 |

55 | 2500 | 300-500 | 4.2*2*3.7 |

|

GM-800 |

95 | 5500 | 500-800 | 10*8*4.5 |

|

GM-1000 |

145 | 8600 | 800-1200 | 15*12*4.5 |

|

GM-1500 |

230 | 11000 | 1500-2000 | 25*20*5.5 |

Raw Materials

Final Product

Flow chart

Place the scrap copper wire/cable into a knife crusher and grind the wire into a granular mixture.The crushed copper and plastic mixture is blown to an air separator by a high pressure blower.The crushed particles are driven by two vibration motors.Due to the different gravity,the copper cladding is easily collected by the blower and further screened by the shaker,while the plastic particles flow out of another discharge hole.At the same time,pulse bag dust collection equipment is used to effectively control dust overflow,dust removal efficiency up to 99%,to ensure no dust pollution.

Product advantages

1.Factory direct sales,quality after sale guarantee,cost-effective.

2.Complete models,but also can be customized according to different needs.

3.Unique negative pressure wind conveying system enables the whole equipment to have the advantages of non-sticking knife,automatic cooling,preventing dust spillover and improving output during operation.

4.Adopt PLC control,make the equipment feed evenly,stable and safe,and have automatic alarm function.

5.Shredding machine adopts high hardness spindle,so that the crusher has more impact force when loading.

6.Increase the current crusher knife type,increase the output by more than 30%,effectively improve the production effect and yield and greatly reduce the investment cost.

7.The combination of air separation equipment and high voltage electrostatic equipment makes the separation rate as high as 99%.

8.The material return system makes the semi-finished products pulverize twice to ensure the complete separation of metal and nonmetal.

9.Adopt new automatic pulse dust removal system,increase 36 bags of new dust removal effect,achieve zero dust emission,to meet the national top environmental protection standards.

10.Convenient maintenance,the new application of convenient disassembly tools,convenient knife change,knife sharpening,replacement of vulnerable parts such as screen mesh,greatly improve the work efficiency,save labor time.

CUSTOMER CASE:

ABOUT US:

Contact Us

If you have any requirement or suggestion, please fill in the form and send to us,or contact us by E-mail :kelly@gmznjx.com thanks!

.png)