- E waste circuit board recycling plant

- PCB disassembly equipment

- Cable Wires Recycling Machine

- Lithium battery recycling plant

- Precious metal refining systems for E-WASTE

- Precious metal refining systems for Catalytics

- Gold Refining And Extraction Equipment

- Precious metal refining systems

- Pt/Pd/Rh purification system equipment

- High efficiency gold electrolytic unit

- High efficiency silver electrolytic unit

- Copper Electrolysis Machine

- Tire Recycling Equipment

- Fully-Automatic Tyre Recycling

- Semi-Automatic Tire Recycling

- Continuous Pyrolysis Plant

- Tyre Pyrolysis Plant

- Aluminum plastic separation plant

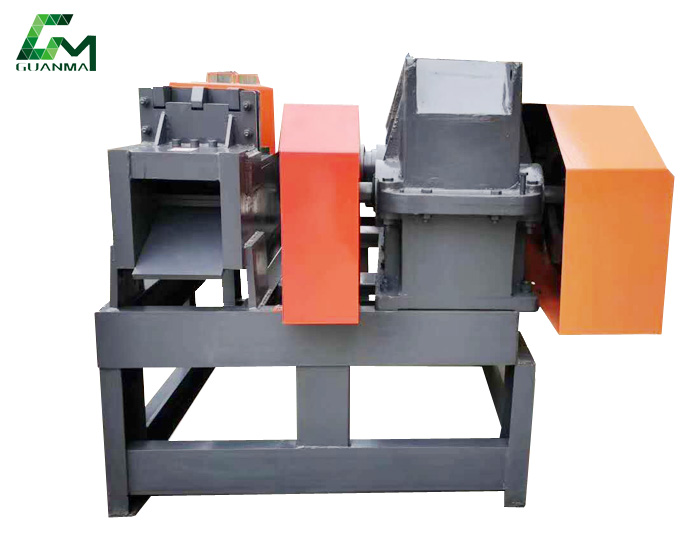

- Double shaft shredder machine

- Waste Refrigerator recycling plant

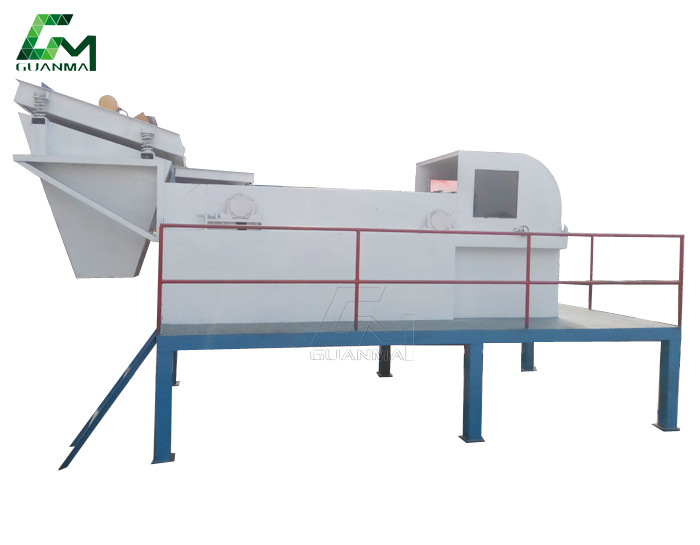

Aluminum Eddy Current Separator

- Product Introduction:

Eddy Current Separator Machine are widely used for ferrous and non ferrous metals separating, such as aluminum Separating, copper separating.

Video Description:

PRODUCT DESCRIPTION:

Aluminum Separating Eddy Current Separator Machine

Machine Introduction:

Eddy current separator (also known as copper-aluminum separator, non-ferrous metal vortex separator, eddy current non-ferrous metal separator). The eddy current separator has good separation effect on a variety of non-magnetic metals, can effectively separate non-metallic materials from non-ferrous metals automatically, and can recover various non-ferrous metals efficiently. The separation process is mechanized and automated to reduce labor costs and increase the added value of products.

After eddy current separator is suitable for the crushing of urban living garbage, industrial waste, electronic waste, scrap, waste plastic doors and Windows, glass urban waste wood, boiler bottom ash, the mixture of a variety of metal, scrap car (after shredding machine section), copper, aluminum and other non-ferrous metal recycling, and materials handling separation in the environmental protection industry, etc.

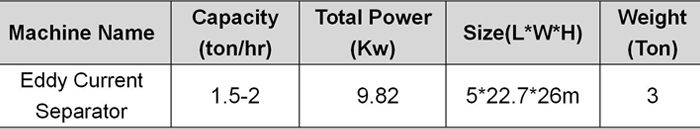

Technical Data of the Ferrous Metals Eddy Current Separator

Working Principle of Eddy Current Separator:

Nonferrous metal vortex separator is designed based on the principle that conductors can generate induced current in high frequency alternating magnetic field. When working, the machine will generate a high frequency alternating strong magnetic field on the surface of the sorting magnetic roller, and induce eddy current inside the metal block. The magnetic field generated by this eddy current is in the opposite direction of the original magnetic field, and there is a mutually repulsive force. The repulsive force can throw the metal block forward to realize the purpose of separation.

Eddy Current Separator Machine features:

1. Simple operation, automatic separation of metal and non-metal; Reliable single power supply design makes the system compact and reliable.

2. The separable metal particles have a large span, ranging from 3mm to 100mm in general.

3, easy to install, according to customer demand tailored, can be effectively connected with the new and existing assembly line.

4, stronger eddy current, using its unique magnetic application technology to develop a more effective separation machine compared with traditional products.

5, the use of high gradient rare earth permanent magnetic system, low energy consumption, easy maintenance.

6. Materials of different particle size can be sorted according to different steering directions of the rotor.

7. Various models are available (the width of the tray is optional from 300mm-1500mm).

8. A variety of rotor designs are available.

Application of Eddy current separator

Eddy current separator is widely used in the crushing of urban living garbage, industrial waste, the repulsive force function can be electronic waste, the gold piece was thrown forward eccentric type choose machine glass broken material, waste plastic doors and Windows, aluminum boiler bottom ash, scrap car after shredding machine slices of copper, aluminum and other non-ferrous metal recycling, and materials handling separation in the environmental protection industry, etc.

Delivery of Aluminum Copper Eddy Current Sorting Machine

ABOUT US:

Contact Us

If you have any requirement or suggestion, please fill in the form and send to us,or contact us by E-mail :kelly@gmznjx.com thanks!

.png)