- E waste circuit board recycling plant

- PCB disassembly equipment

- Cable Wires Recycling Machine

- Lithium battery recycling plant

- Precious metal refining systems for E-WASTE

- Precious metal refining systems for Catalytics

- Gold Refining And Extraction Equipment

- Precious metal refining systems

- Pt/Pd/Rh purification system equipment

- High efficiency gold electrolytic unit

- High efficiency silver electrolytic unit

- Copper Electrolysis Machine

- Tire Recycling Equipment

- Fully-Automatic Tyre Recycling

- Semi-Automatic Tire Recycling

- Continuous Pyrolysis Plant

- Tyre Pyrolysis Plant

- Aluminum plastic separation plant

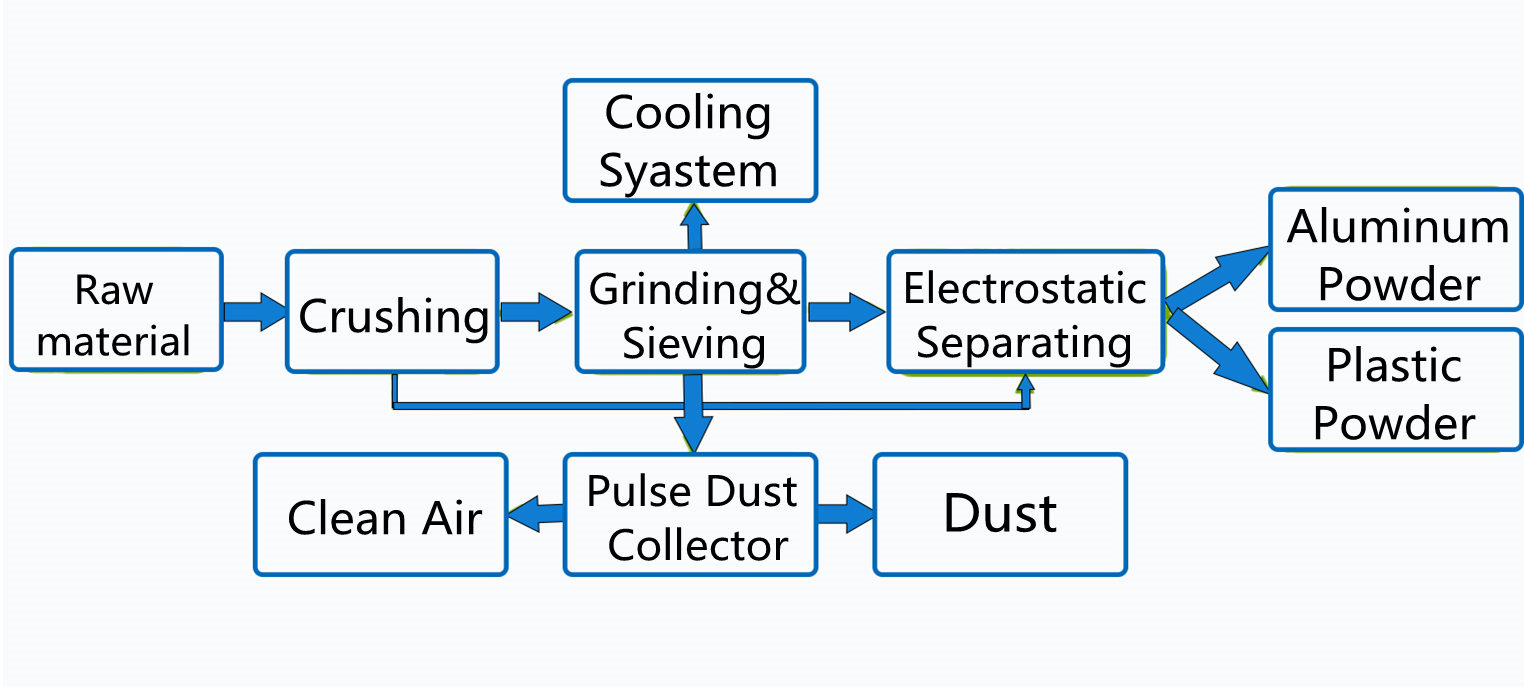

- Double shaft shredder machine

- Waste Refrigerator recycling plant

Aluminum plastic separation plant

- Product Introduction:

Capacity:300-1000 Kg/H

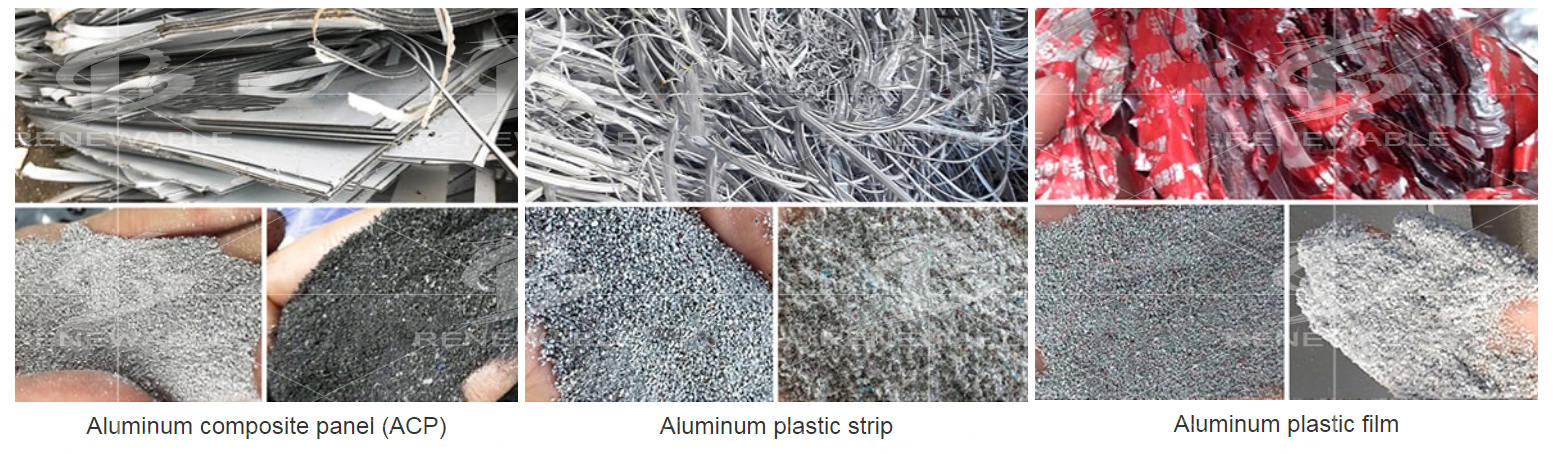

Raw Materials:ACP (Aluminous Composite Panel), Medicine Blisters, Food Packaging Bags, Toothpaste Tube, Al-plastic Combined Caps, etc.

Final Products:Aluminum Powder, Plastic Powder

Video Description:

PRODUCT DESCRIPTION:

Raw materials and final products

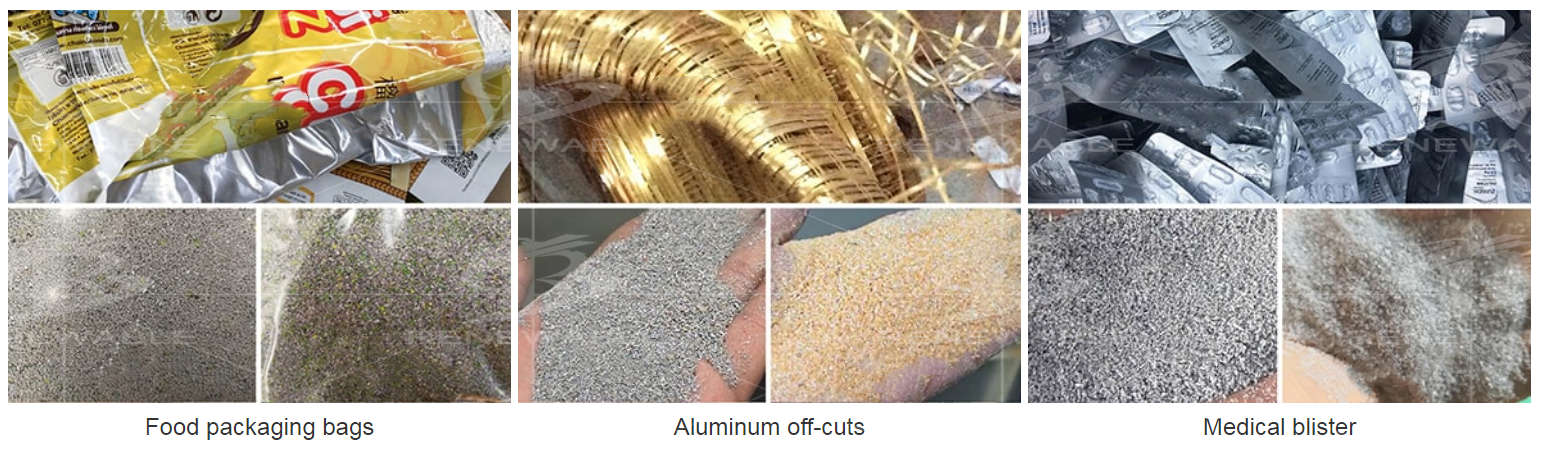

Flow chart

First through the knife crusher coarsely crushed into the following 10mm sheet material,it then enters a high-speed cold water turbine mill to pulverize the sheet into a mixture of aluminum and plastic,the spin vibration sieve screening materials conform to the requirements by using the theory of electrostatic separator separating the aluminum and plastic,unqualified material returned to mill continue to crush and then through the electrostatic separation of aluminum and plastic powder separation process,To prevent dust pollution in the production process,add pulse dust removal device after grinding,effectively solve the problem of dust pollution.

Product advantages

High automation program, simple operation, stable performance;

1. Low power consumption, low noise, small footprint, no dust pollution;

2. electrical separation efficiency of 99%, the finished products can be directly sold;

3. wide range of sorting materials, sorting speed is fast;

4. no waste gas emissions, real green environmental protection sorting, no secondary pollution generation;

The aluminum-plastic sorting and recycling equipment adopts water-cooled and air-cooled turbine mill, which makes the material separation cleaner and more suitable for a wider variety of materials.

Technical Parameter

|

Model |

Power(kw) |

Size(mm) |

Sorting rate |

Dust removal efficiency |

Output(kg/h ) |

|

LS-300 |

110 |

7500*5000*4500 |

>98% |

99% |

100-300 |

|

LS-500 |

140 |

8500*5000*4500 |

>98% |

99% |

300-500 |

|

LS-1000 |

270 |

13000*10000*4500 |

>98% |

99% |

800-1000 |

ABOUT US:

Contact Us

If you have any requirement or suggestion, please fill in the form and send to us,or contact us by E-mail :kelly@gmznjx.com thanks!

.png)