- E waste circuit board recycling plant

- PCB disassembly equipment

- Cable Wires Recycling Machine

- Lithium battery recycling plant

- Precious metal refining systems for E-WASTE

- Precious metal refining systems for Catalytics

- Gold Refining And Extraction Equipment

- Precious metal refining systems

- Pt/Pd/Rh purification system equipment

- High efficiency gold electrolytic unit

- High efficiency silver electrolytic unit

- Copper Electrolysis Machine

- Tire Recycling Equipment

- Fully-Automatic Tyre Recycling

- Semi-Automatic Tire Recycling

- Continuous Pyrolysis Plant

- Tyre Pyrolysis Plant

- Aluminum plastic separation plant

- Double shaft shredder machine

- Waste Refrigerator recycling plant

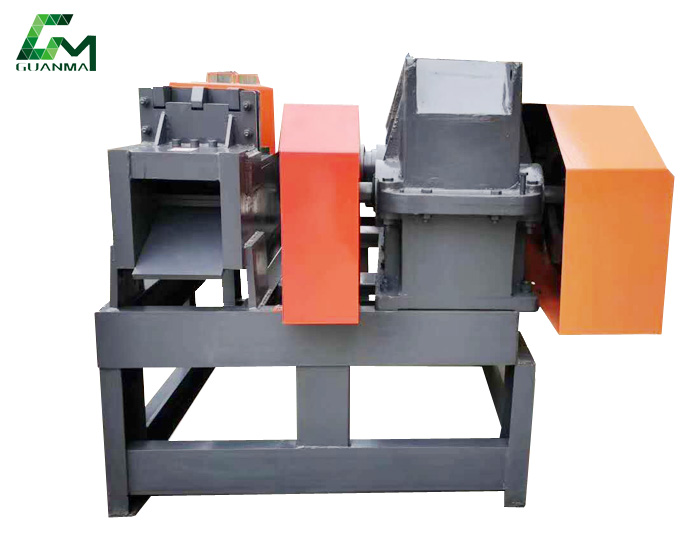

Copper Electrolysis Machine

- Product Introduction:

Copper Electrolysis Machine is used for refine the copper from the mixed metal powder, the purity of finished copper is as high as 99%.Copper electrolysis system is composed of a number of automatic IGBT power control module, belonging to digital pulse power equipment.....

Video Description:

PRODUCT DESCRIPTION:

.jpg)

The Separated metal part be smelted and cast into anode board for the process of copper electrolysis.

since a large number of non-ferrous metals, rare earth metals and precious metals are used in the

production of the circuit board , if in conventional electrolytic method,the anode often get passivated

and causing electrolysis can not work normally. Here we suggest adopting pulse automatic pole changing

electrolysis system, it not only solve the anode passivation problem effectively, but also help anode

mud loose off. The time is set and adjusted arbitrarily by the control cabinet.

Copper electrolysis system is composed of a number of automatic IGBT power control module, belonging

to digital pulse power equipment. Semiautomatic formwork mold is adopted during casting of the anode

plate, and in order to shorten the electrolysis cycle, the anode thickness is generally controlled to

10 mm to 30 mm.

Production Process:

.jpg)

In the electrolysis, Cu2+ obtains the the electron and turns into pure copper at the cathode. At the

same time, gold, silver, palladium and the platinum remains in the anode mud. the anode mud be washed,

undertake reducing smelting and oxidation smelting in frequency furnace, then we can get the precious

metal alloy block. Then have it water broken, and then through the precious metal to make liquid

extraction separation and refining a variety of precious metals.

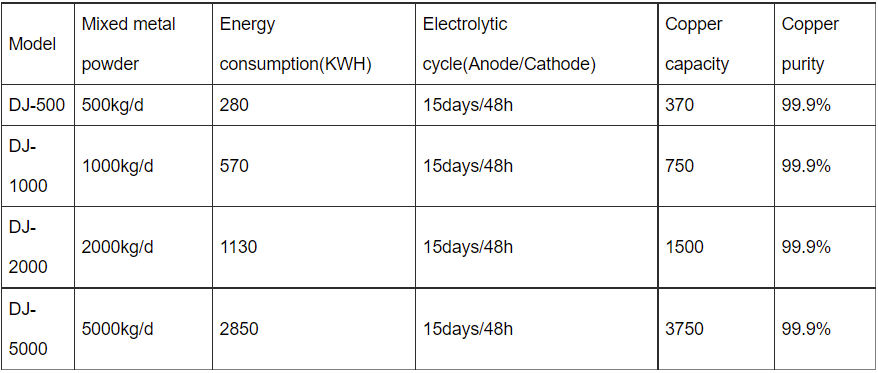

Technical parameters:

Main characteristics:

In the workshop, all place producing exhausting gas must be set up tail gas absorption device with the

ozone, all places producing tail liquid must establish fluid diversion device, the tail liquid will

be lead to the waste water treatment plant and be discharged or reused after meet the standard.

1. After processing the tail liquid can be consistent with national environmental requirements.

2. The recovery rate of gold, silver, palladium and platinum can be above 99% and the purity of

precious metals can be above 99%.

3. Automatic controlling, compared with other processes, labor costs can be reduced by 90%.

4. The exhaust gas treatment system can produce useful chemicals, creating added value

5. Advanced technology make the electrolytic cycle much shorter.

6. The use of automatic control system for exhaust emissions, in full compliance with national

environmental requirements "air pollutant discharge standards", no secondary pollution.

Customer Case:

(1).jpg)

.jpg)

.png)

ABOUT US:

Contact Us

If you have any requirement or suggestion, please fill in the form and send to us,or contact us by E-mail :kelly@gmznjx.com thanks!

.png)