- E waste circuit board recycling plant

- PCB disassembly equipment

- Cable Wires Recycling Machine

- Lithium battery recycling plant

- Precious metal refining systems for E-WASTE

- Precious metal refining systems for Catalytics

- Gold Refining And Extraction Equipment

- Precious metal refining systems

- Pt/Pd/Rh purification system equipment

- High efficiency gold electrolytic unit

- High efficiency silver electrolytic unit

- Copper Electrolysis Machine

- Tire Recycling Equipment

- Fully-Automatic Tyre Recycling

- Semi-Automatic Tire Recycling

- Continuous Pyrolysis Plant

- Tyre Pyrolysis Plant

- Aluminum plastic separation plant

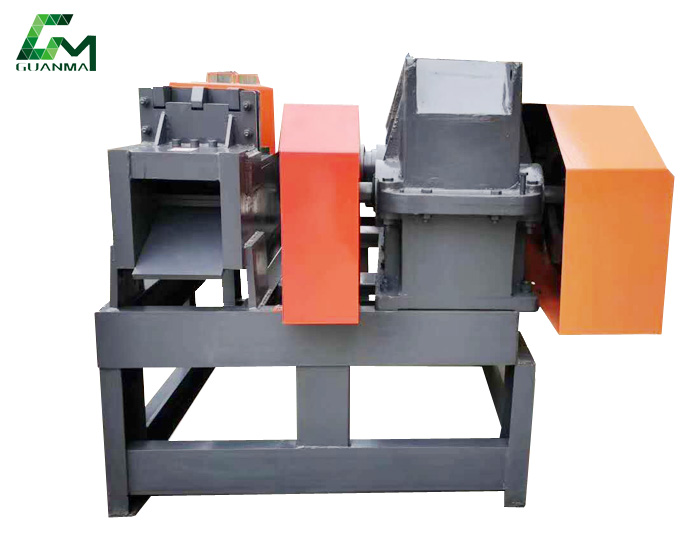

- Double shaft shredder machine

- Waste Refrigerator recycling plant

Gold Refining And Extraction Equipment

- Product Introduction:

was specially designed to strip gold from gold-plated materials that come from those obsolete and junked electronic products, which is currently the best gold extraction method. By using this system, the recovery rate of gold is up to 99%.....

Video Description:

PRODUCT DESCRIPTION:

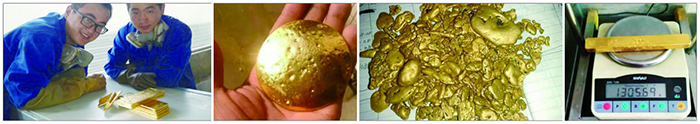

Gold Deplating System was specially designed to strip gold from gold-plated materials that come from those obsolete and junked electronic products, which is currently the best gold extraction method. By using this system, the recovery rate of gold is up to 99%, and you can get high-purity gold after further refining.

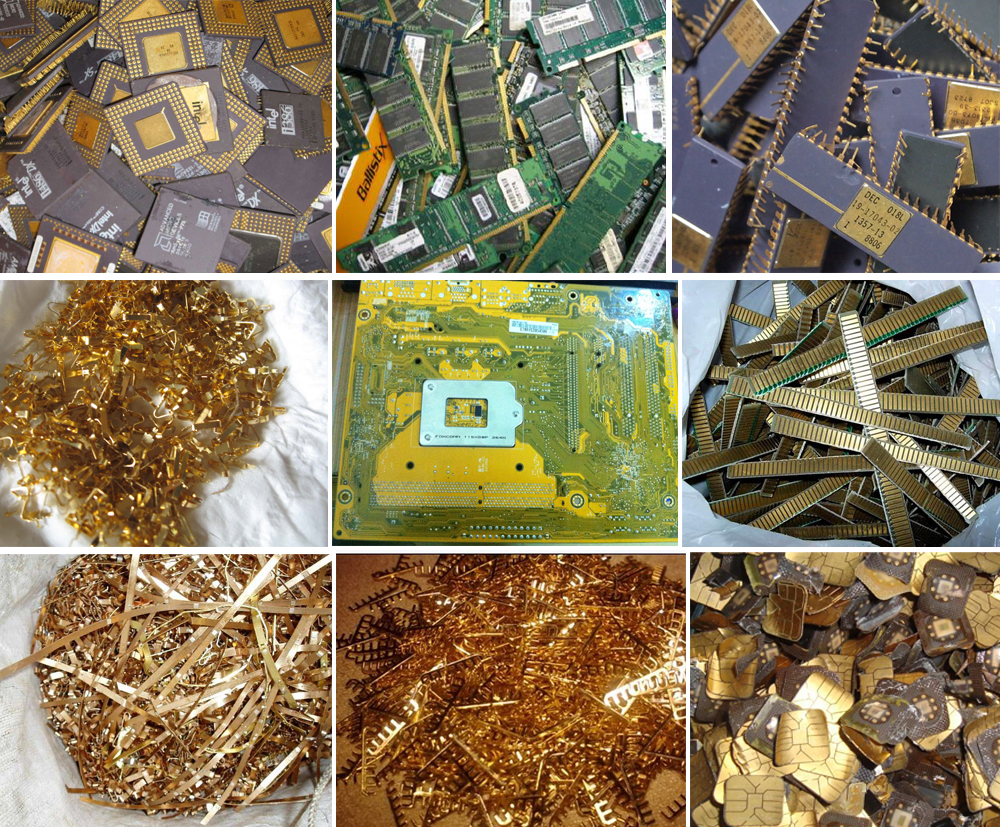

Gold Deplating System applies to various gold-plated scraps generated in our daily life, such as waste cellphone circuit boards, computer CPUs, motherboards, VCDs, DVDs, TVs, game consoles, fax machines, telephone sets and many other old domestic appliances, as well as those leftovers and off-cuts from the electroplating factory, electronic components manufacturing factory,printing house, photosensitive materials plant.

APPLICATION

FINAL PRODUCTS

1.Dispensing the gold stripping solution.

2.Put the surface plated materials into liquid, then the surface gold dissolved in the gold stripping solutions, no other metal like lead, nickel, iron, or any other metal be dissolved in the solution. (our patent product)

3.Filtering to remove the impurity

4.Reduction: Add the reduction powder to the solutions, the gold will be extracted and turn into black powder, Get the black powder settle down, then finally we get the crude gold powder.

TECHNICAL PARAMETERS

| MOdel | Capacity |

Power |

|

GM-100 |

100-200kg/H | 25KW |

|

GM-200 |

200-300kg/H | 40KW |

Customer Case:

Test and inspection:

Before delivery, we all equipment will imitate the real production environment, use the customer need to deal with material test, to ensure the production line performance and production meet

customer requirement. We sincerely invite customers came to the scene for final test.

ABOUT US:

Contact Us

If you have any requirement or suggestion, please fill in the form and send to us,or contact us by E-mail :kelly@gmznjx.com thanks!

.png)