- E waste circuit board recycling plant

- PCB disassembly equipment

- Cable Wires Recycling Machine

- Lithium battery recycling plant

- Precious metal refining systems for E-WASTE

- Precious metal refining systems for Catalytics

- Gold Refining And Extraction Equipment

- Precious metal refining systems

- Pt/Pd/Rh purification system equipment

- High efficiency gold electrolytic unit

- High efficiency silver electrolytic unit

- Copper Electrolysis Machine

- Tire Recycling Equipment

- Fully-Automatic Tyre Recycling

- Semi-Automatic Tire Recycling

- Continuous Pyrolysis Plant

- Tyre Pyrolysis Plant

- Aluminum plastic separation plant

- Double shaft shredder machine

- Waste Refrigerator recycling plant

PCB disassembly equipment

- Product Introduction:

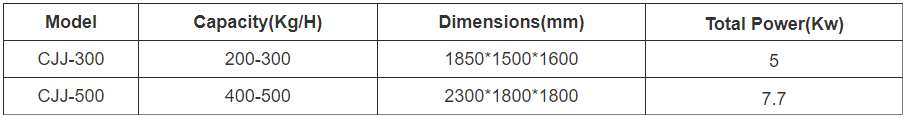

Capacity:200-500 Kg/h

Raw Materials:Computer board, Phone board, TV board,etc

Final Products:Mother Boards, Electronic components

Video Description:

PRODUCT DESCRIPTION:

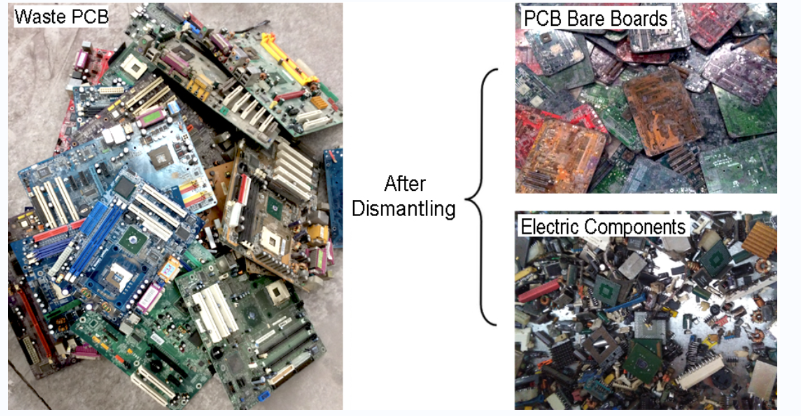

Automatic circuit board disassembly equipment is composed of circuit board disassembly machine and waste gas

treatment equipment,mainly used to disassemble electronic components from the waste circuit board,because

different components contain different metals,some components contain gold,silver,palladium and other precious

metals,while some components contain toxic substances;Some components can be sorted and sold directly;The

disassembled motherboard is also easier to break and separate copper,which greatly reduces the work of the

crushing and sorting section and improves the recycling rate of precious metals.

Technical Parameter

Raw material

Finished Product:

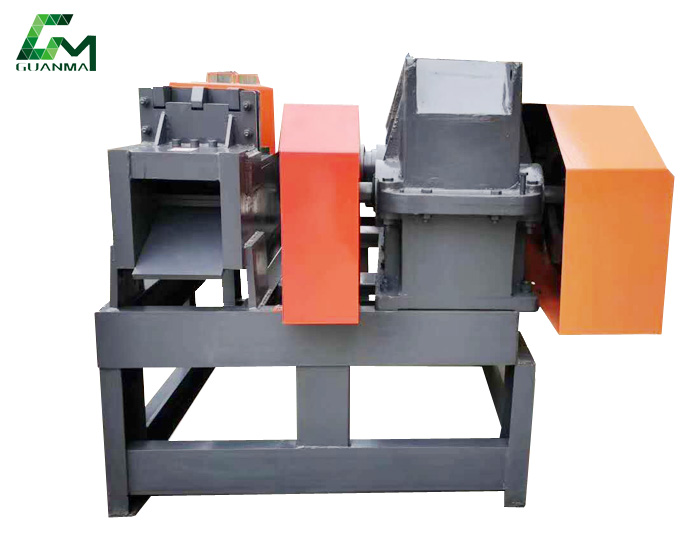

The automatic circuit board disassembly equipment melts the tin on the circuit board by heating it and then uses

rolling friction to separate the electronic components from the motherboard.In this process,the exhaust gas is

absorbed by activated carbon to treat the formaldehyde,and then water is sprayed to precipitate the exhaust gas.

Features

1.Full automatic working,save labor,two persons are enough;

2.Tin remove and dismantling components at one step,Automatic temperature controlled by our heating system;

3.Large capacity:300kg/h,500kg/h,Operating safety and easily;

4.Less damage to the components,keep the precious metals no losing;

5.Mother board and components can be proceed respectively in the next step to improve economic benefits;

6.Friendly to the air environment,all the smoke processing by the waste gas treatment system.

Customer Case:

ABOUT US:

Contact Us

If you have any requirement or suggestion, please fill in the form and send to us,or contact us by E-mail :kelly@gmznjx.com thanks!

.png)