- E waste circuit board recycling plant

- PCB disassembly equipment

- Cable Wires Recycling Machine

- Lithium battery recycling plant

- Precious metal refining systems for E-WASTE

- Precious metal refining systems for Catalytics

- Gold Refining And Extraction Equipment

- Precious metal refining systems

- Pt/Pd/Rh purification system equipment

- High efficiency gold electrolytic unit

- High efficiency silver electrolytic unit

- Copper Electrolysis Machine

- Tire Recycling Equipment

- Fully-Automatic Tyre Recycling

- Semi-Automatic Tire Recycling

- Continuous Pyrolysis Plant

- Tyre Pyrolysis Plant

- Aluminum plastic separation plant

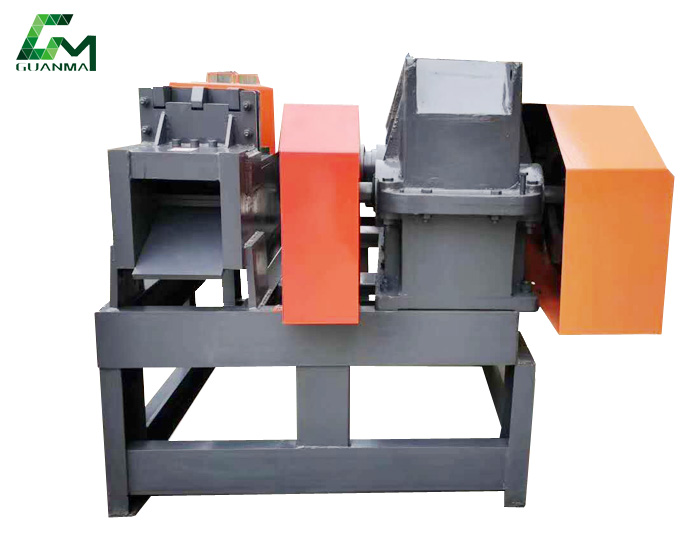

- Double shaft shredder machine

- Waste Refrigerator recycling plant

Lithium battery recycling plant

- Product Introduction:

At present, the research on the recycling of waste lithium batteries is mainly focused on the recovery of high-value anode precious metals cobalt and lithium. Copper in the negative electrode of waste lithium battery( content up to 35%) is an important production raw material widely used Carbon powder adhered to it can be used as additives such as plastics and rubber. Based on the structural characteristics of lithium batteries, our company adopts an environmentally-friendly physical separation process to realize efficient separation and recovery of waste lithium batteries. The

Video Description:

PRODUCT DESCRIPTION:

At present, the research on the recycling of waste lithium batteries is mainly focused on the recovery of high-value anode precious metals cobalt and lithium. Copper in the negative electrode of waste lithium battery( content up to 35%) is an important production raw material widely used Carbon powder adhered to it can be used as additives such as plastics and rubber. Based on the structural characteristics of lithium batteries, our company adopts an environmentally-friendly physical separation process to realize efficient separation and recovery of waste lithium batteries. The lithium battery recycling production line is used for dismantling and recycling the Soft package battery, cellphone battery, Shell batter Cylindrical battery etc.

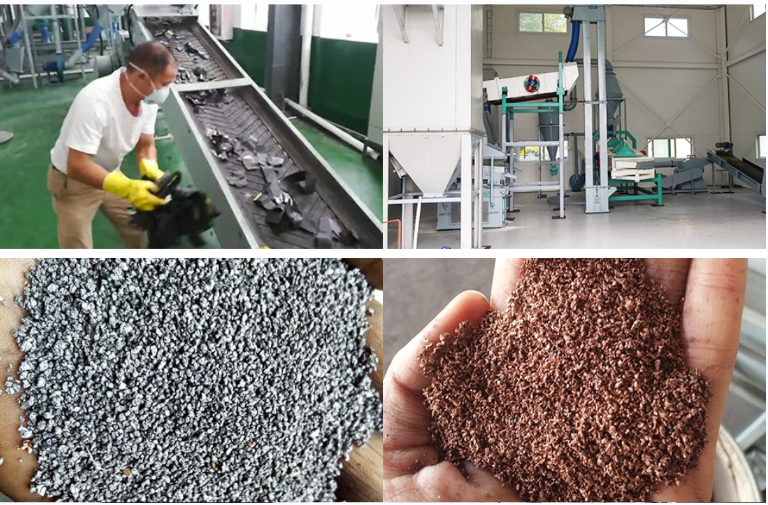

The final products of this plant is Graphite powder, Cobalt acid lithium Aluminum and Copper.

Raw Materials:

recycling plant is used for dismantling and recycling the soft package battery, cellphone battery, shell battery, cylindrical battery etc.Different types of lithium batteries have different recycling procedures.

Final Product:

The final product is graphite powder, cobalt acid lithium, aluminum and copper..

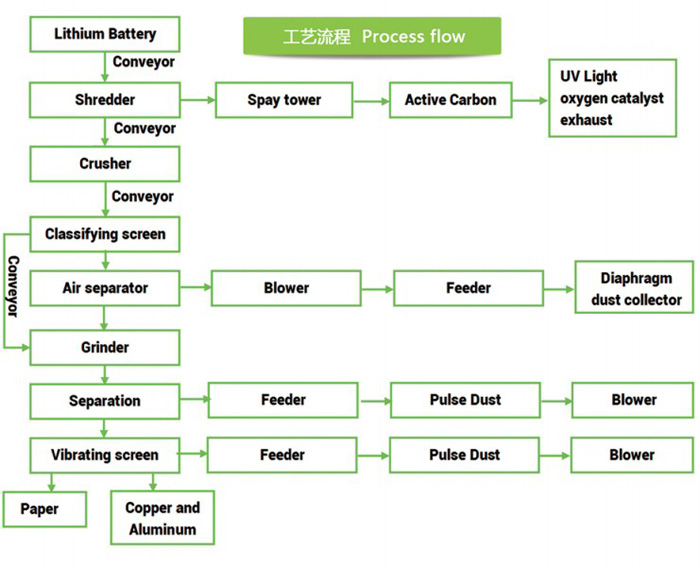

Technical Process:

The process mainly comprises the following steps: after discharging the recovered waste batteries, crushing, magnetic separation, air separation, crushing, gravity separation, screening and other processes are carried out by mechanical equipment.

Technical Standards:

| Feature Item |

Indicator Requirments |

|

Recovery Rate of Metallic Aluminum

|

>98% |

| Powder Recovery Rate |

>98% |

| Content of Powder In Metal Aluminum |

<2% |

| Other |

Contain dust collecter with not pollute |

| Qualified Rate |

99% |

| Failure Rate |

<1% |

| CMR |

≥1.67 |

Note : Processing capacities are the average value, depending on the capacity, the number of stand-alone units is different, Please inquire according to your needs.The pretreatment process of waste lithium ion batteries mainly comprises the following steps: after discharging the recovered waste batteries, crushing, magnetic separation, air separation, crushing. gravity separation, screening and other processes are carried out by mechanical equipment, so that the powder on the positive and negative pole pieces is effectively separated from the copper aluminum foil, and the batteries are treated as valuable materials.

Technical Parameters:

|

Model |

Capacity | Poder |

|

GM—LDC-500 |

300-500kg/H | 55KW |

|

GM—LDC-800 |

500-800kg/H | 85KW |

|

GM—LDC-1000 |

800-1000kg/H | 120KW |

|

GM—LDC-1200 |

1000-1500kg/H | 200KW |

WORKING PERFORMANCE:

|

Raw Material |

Lithium Battery |

|

Final Product |

Mainly Copper, Aluminum, Lithium Cobalt Oxide, Graphite Powder |

Customer Worksite:

1000 Kg/H Lithium Battery Recycling Plant In South Korea

ABOUT US:

Contact Us

If you have any requirement or suggestion, please fill in the form and send to us,or contact us by E-mail :kelly@gmznjx.com thanks!

.png)