- E waste circuit board recycling plant

- PCB disassembly equipment

- Cable Wires Recycling Machine

- Lithium battery recycling plant

- Precious metal refining systems for E-WASTE

- Precious metal refining systems for Catalytics

- Gold Refining And Extraction Equipment

- Precious metal refining systems

- Pt/Pd/Rh purification system equipment

- High efficiency gold electrolytic unit

- High efficiency silver electrolytic unit

- Copper Electrolysis Machine

- Tire Recycling Equipment

- Fully-Automatic Tyre Recycling

- Semi-Automatic Tire Recycling

- Continuous Pyrolysis Plant

- Tyre Pyrolysis Plant

- Aluminum plastic separation plant

- Double shaft shredder machine

- Waste Refrigerator recycling plant

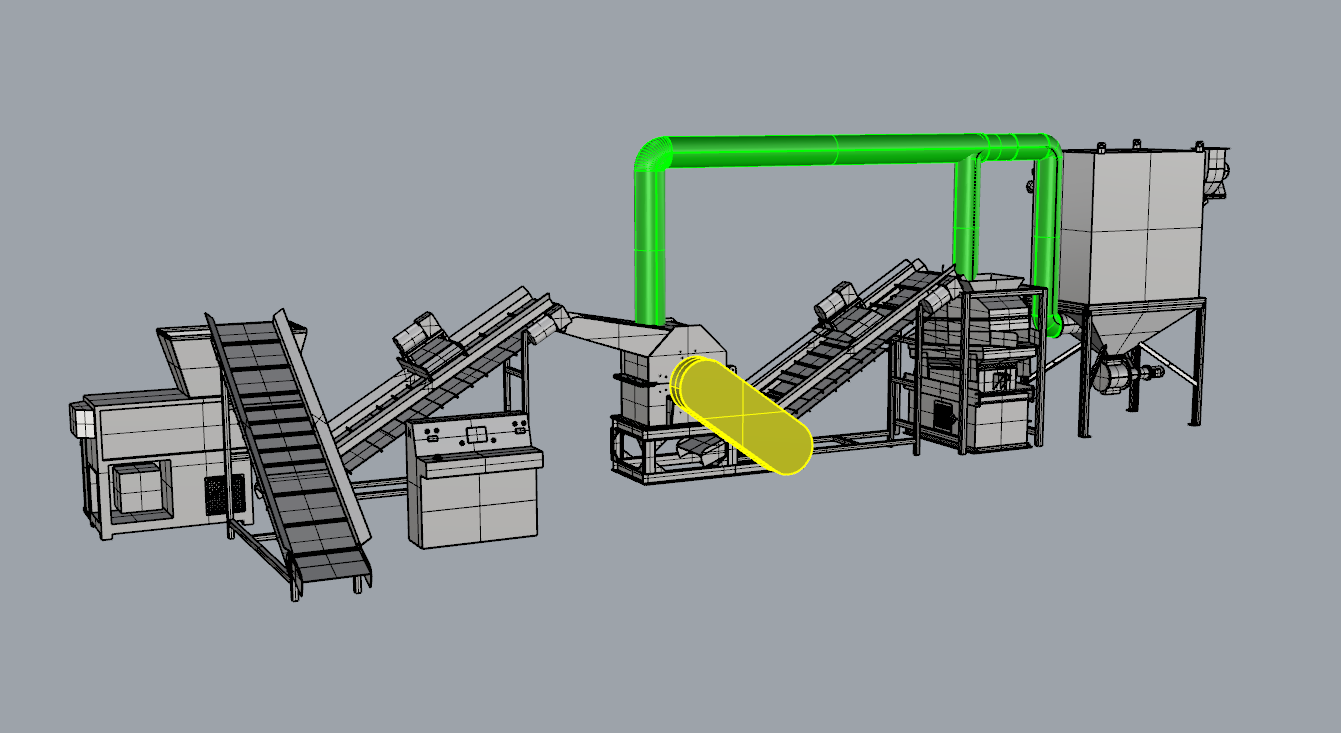

Video Description:

PRODUCT DESCRIPTION:

APPLICATION:

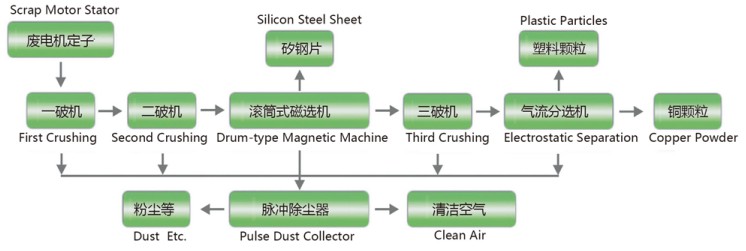

TECHNOLOGY INTRODUCTION:

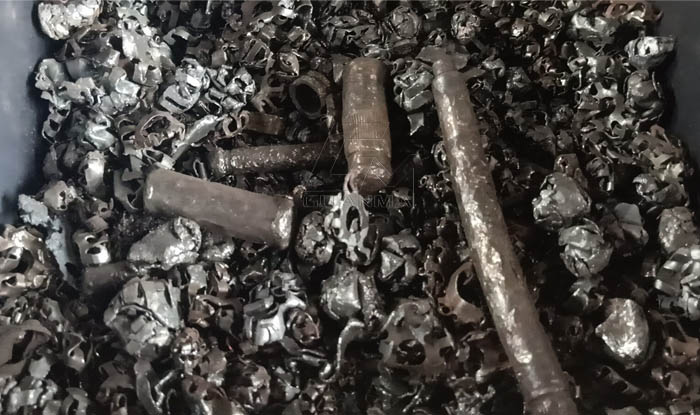

Physical way to recycle the scrap motor stator, controlled by PLC. The manually selected stators, coils are transported to first crusher, second crusher, then through magnetic separator to separate iron and copper. The copper mixture is transferred to grinder to get smaller granules, then to air separator to get purifier copper granular. The machine can reach a considerable economic benefits. The dust caused by crush and separation will catched by pulse dust collecting system, which will prevent the environment from dusts pollution. The machine is meet the standard GB16297-1996.

TECHNICAL PARAMETER:

Note : Processing capacities are the average value, depending on the capacity, the number of stand-alone units is different, Please inquire according to your needs.

|

Model |

Power | Weght | Size(M) | Capacity |

| DZ-1000 | 177KW | 26Ton | 25*6*6 |

1t/h |

| DZ-2000 | 303KW | 47Ton | 40*6*6 |

2t/h |

| DZ-3000 | 355KW | 50Ton | 45*6*6 |

3t/h |

| DZ-5000 | 498KW | 67.5Ton | 50*6*10 |

5t/h |

.png)

TECHNOLOGY INTRODUCTION:

FEATURES:

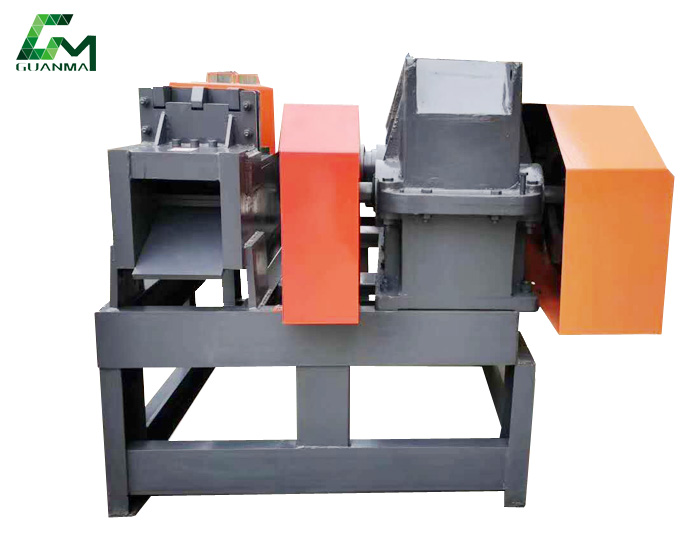

1.Controlled by PLC, the whole machine works in stable way

2.Easy construction, stable running, little vibration and low noise

3.First crusher is equipped with two axis, with the advantage of low noise, large torque and big crushing

4.The shredder use the special alloy blades, own the ability to shredding, pull-apart, and extruding, cacrush different materials easily

5.The second crusher is tear-type, consist of tinny cutter and cylinder shank, which reduce the cost of wearing parts. The diameter of the axis in second grinder is 360mm, making bigger compact on the material. The blades adopt the minitype cutting bit and the column cutter bar, and reduce the wearing parts cost.

6.netic separator is made of two roller separators, to make sure the separate rate up to 97%: and the eparator make the copper more clean and high purity

7.Dedusting separation of pulse dust catcher can reach 99, 99%. Not only catch the dust, but also meet the environmental requirements(gb16297-1996)

CUSTOMER SITE:

ABOUT US:

Contact Us

If you have any requirement or suggestion, please fill in the form and send to us,or contact us by E-mail :kelly@gmznjx.com thanks!

.png)